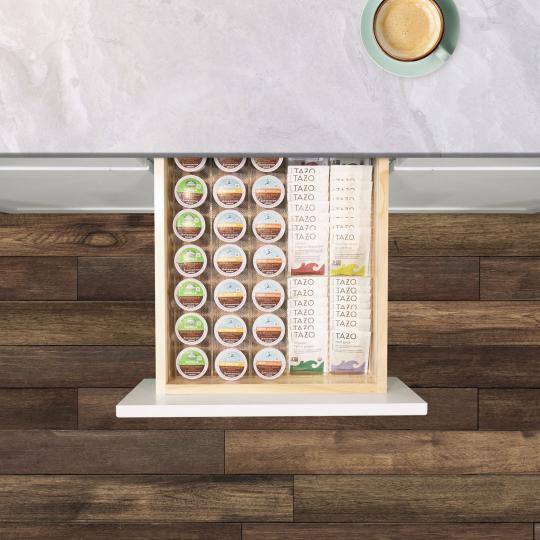

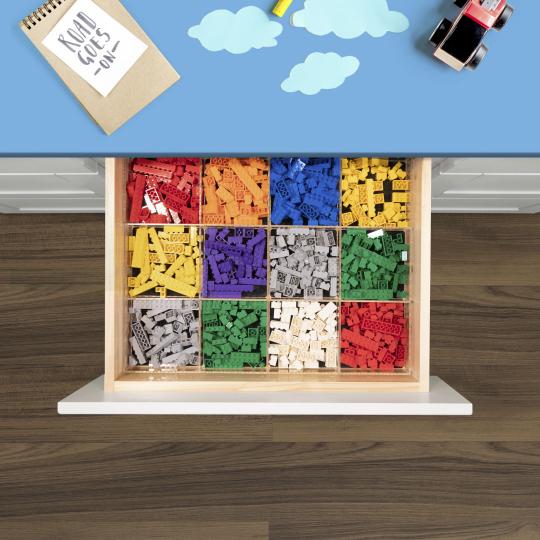

Organization on your terms.

Create a custom organizer to fit your unique needs. Design your acrylic organizers to your exact specifications and dimensions. Start your design with one of our popular templates or start from scratch to create the perfect solution.

Start Designing